Label Inspection

Lable Inline Inspection System

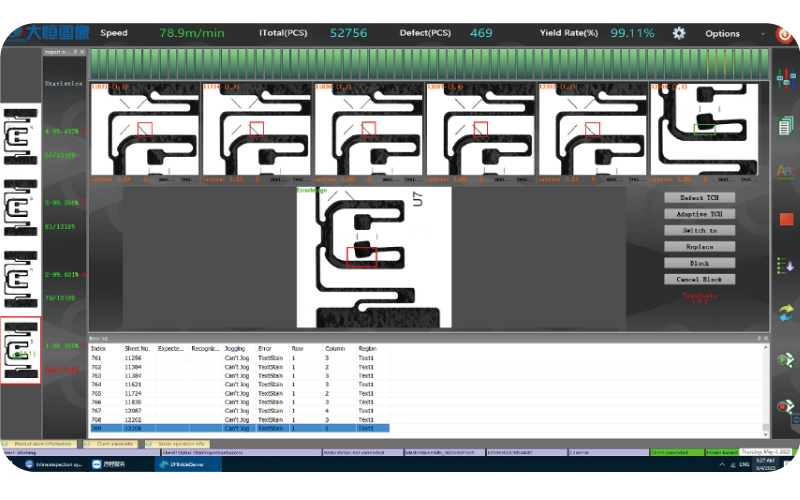

Label inline inspection system is installed on full-rotary, flexo press, gravure press and offset press machine to real time inspect print quality. Inspection system can be applied for quality control during printing process to avoid continuous waste. When defects are detected, system will alert operator with sound and light.

- Product Features

-

Software can analyze the regions of pattern and variable code, and create template automatically

Software supports to set up inspection parameters for flexible quality control

Software can inspect QR code, barcode and numeric character in various fonts

System can store defect information and classify by types

Sticker device, ink-jet device and marker pen are optional

Products Overview

Specifications

| Item | Specification | |

|---|---|---|

| Max. inspection width | 350mm | |

| Imaging resolution | 4K color camera:0.08mm(W)×0.08mm(L) | 8K color camera:0.04mm(W)×0.04mm(L) |

| Max. Inspection speed | 200m/min | 150m/min |

| Inspected print defects | Dirt, missing print, deviation, poor trash-cleaning, color variance, mis-registration, etc. | |

| Min. defect size | High contrast:0.03mm² Low contrast:0.1mm² | High contrast:0.01mm² Low contrast:0.05mm² |

| Min. inspected registration | ±0.1mm | ±0.05mm |

| Color variance | △E ≥ 3 | |

| Variable data type | Number code Bar code:Code128、ITF25、EAN13、Code39、EAN8、UPCA、 UPCE、UCC/EAN-128、CODABAR、etc. QR code:QR、DM、PDF417 | |

| Inspected coding rule of variable data | sequence code, ink-jet code, related code wrong code, repetition, absence, bad code | |

| Min. defect of size | number: 2mm×1.5mm barcode:width of thinnest line 0.3mm QR code:8mm×8mm (Min. width and height of cube 0.3mm) | number:1mm×0.8mm barcode:width of thinnest line 0.15mm QR code:5mm×5mm (Min. width and height of cube 0.3mm) |

CONSULTATION

15F Daheng Science & Technology Tower, No.3 Suzhou Str., Haidian District, Beijing China

+8610-82362836

E-mail: consult@daheng-imaging.com