Solutions

Solutions

01/ 01

-

- Beijing Headquarters

-

-

-

-

-

-

-

-

-

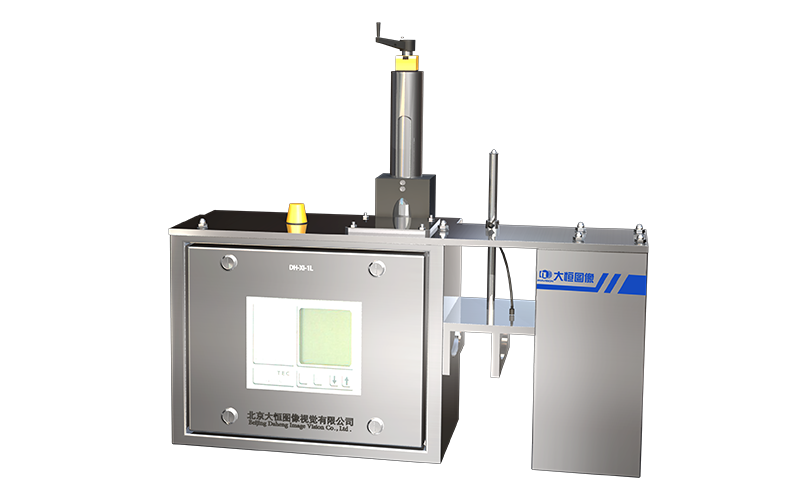

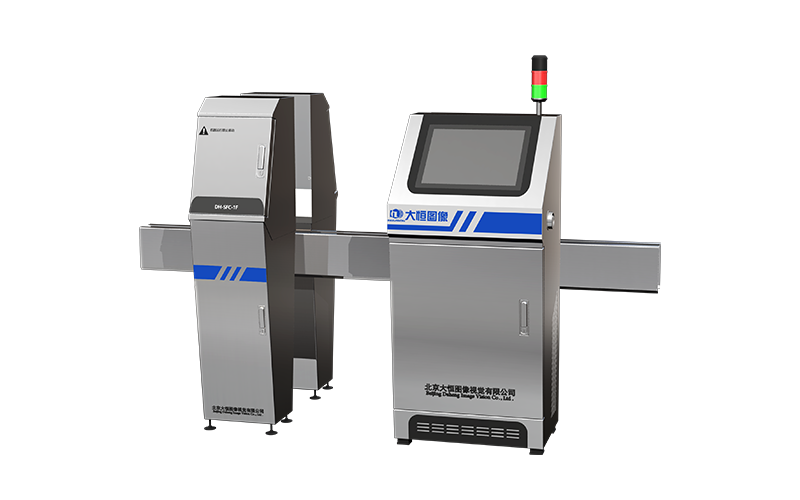

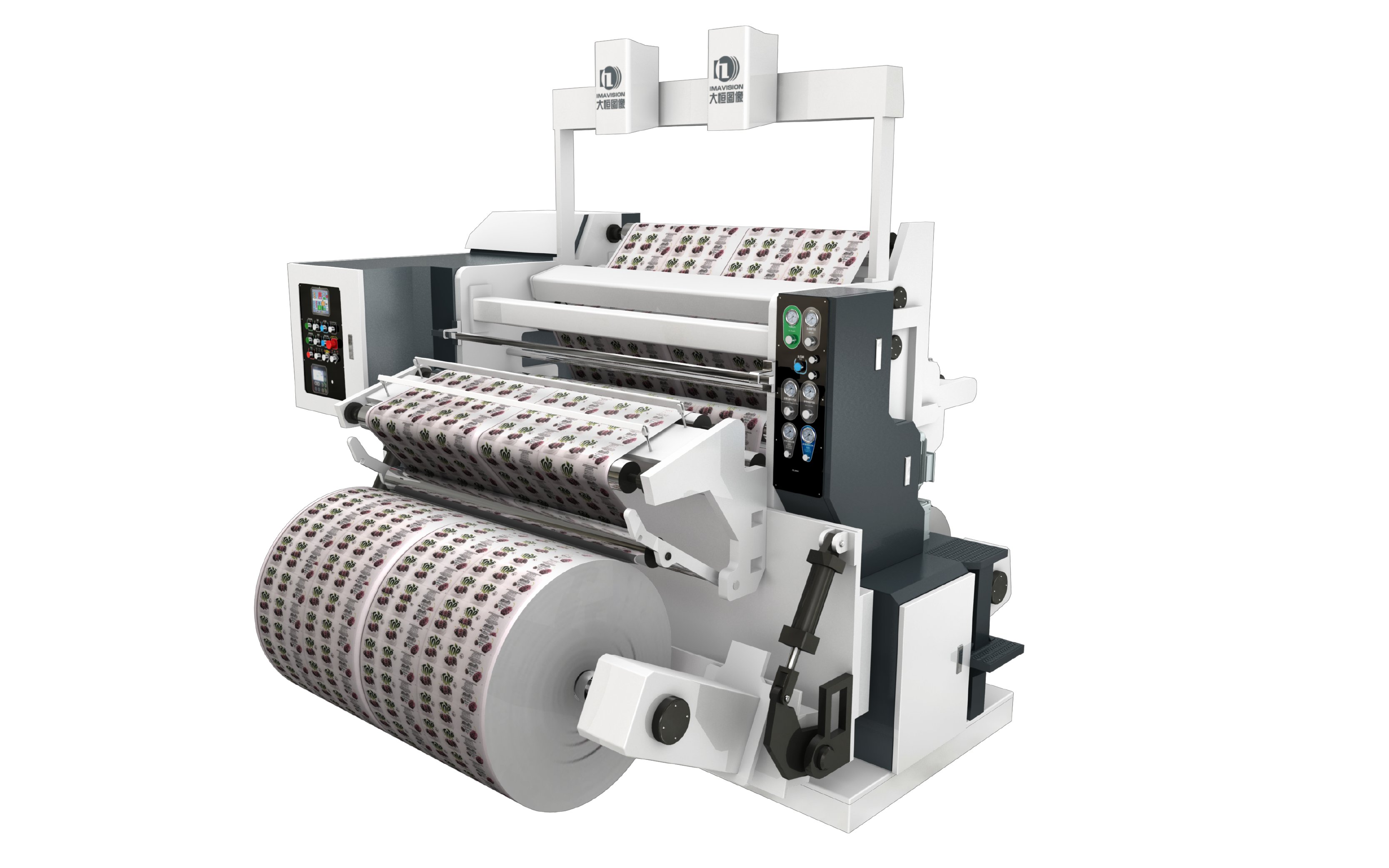

Beijing Daheng Image Vision Co.,Ltd.

Beijing Daheng Image Vision Co., Ltd. was founded in 1991,which is the core asset of a listed company “Daheng Tech”(Stock Code: 600288),has been dedicated to the advancement of machine vision technologies

-

0Foundation 1991

-

07 Offices

-

0 +Projects More Than

500 Regions