Keep Exploring

Outstanding Technologies High-quality Products Superior Services

Promote the society by image vision application

Keep Exploring

Outstanding Technologies High-quality Products Superior Services

Promote the society by image vision application

- Printing Inspection

- Bottle Inspection

- Pharmacy & Canning Inspection

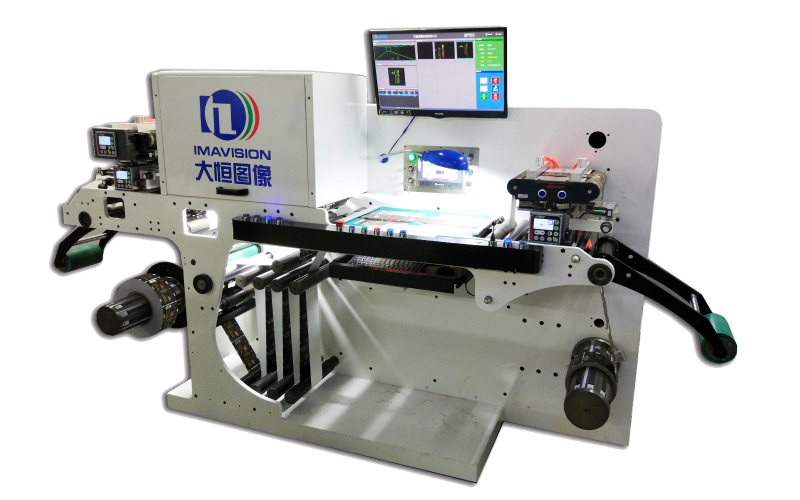

- Label Inspection

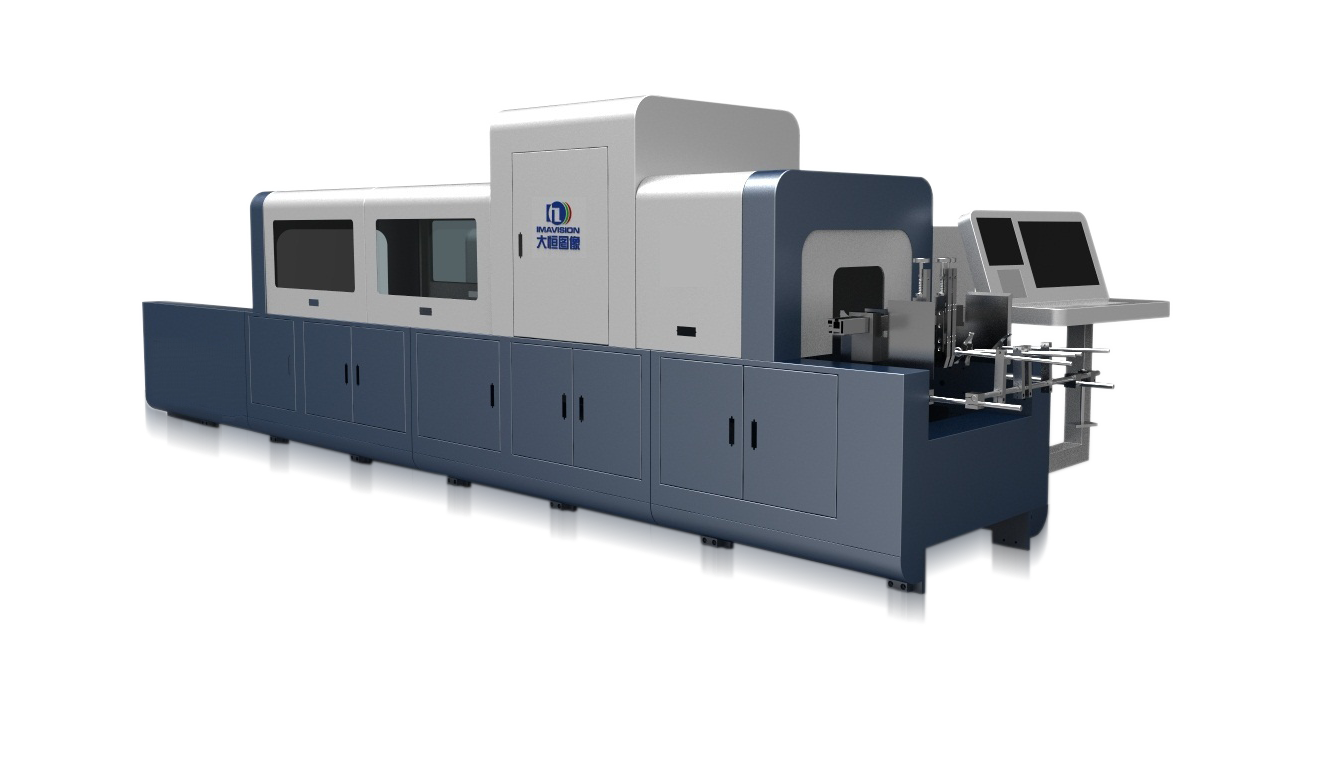

High-speed handling, inspection of up to 130,000 sheets per hour with a delivery rate of up to 300 meters per minute

Versatile inspection, multi-check points design to detect all the defects

Two-in-one design to support both quality inspection and folding-gluing operations, helping customers maximize productivity and minimize labor costs

Replaces manual labor with 24-hour high-speed work without fatigue and allows for rapid switching between inspected products

Multi-station design for comprehensive print process inspection, customizable for special process checks

Quick modeling, with modeling taking only 3 minutes

Replaces manual labor with 24-hour high-speed work without fatigue and allows for rapid switching between inspected products

Image capture accuracy reaches 0.05mm

Double-sided printing inspection, variable information recognition, and customizable special process inspections

Modular design: different modules to choose according to function needs, good adaptability

Innovative design of delivery module to completely avoid scratches on the surface of prints

Able to be paired with various folder gluer, different models (550, 650, 800, 1100) are available to choose according to customers'needs

Connected with feeder of folder gluer machine to complete both quality inspection and folding-gluing operations, helping customers maximize productivity and minimize labor costs

Modular design: different modules to choose according to function needs, good adaptability

Support for setting up master within 3~5 min for quick inspection

Organized interface displays defect in accordance with label inspection feature and operation habit

Versatile inspection, multi-check points design to detect all the defects generated in printing processes like foil stamping, holographic printing, embossing,varnishing, etc

Three steps to set up: scan production sample, load PDF template, and inspect the sample

Software supports to identify and separate printed and non-printed la yers in PDF file

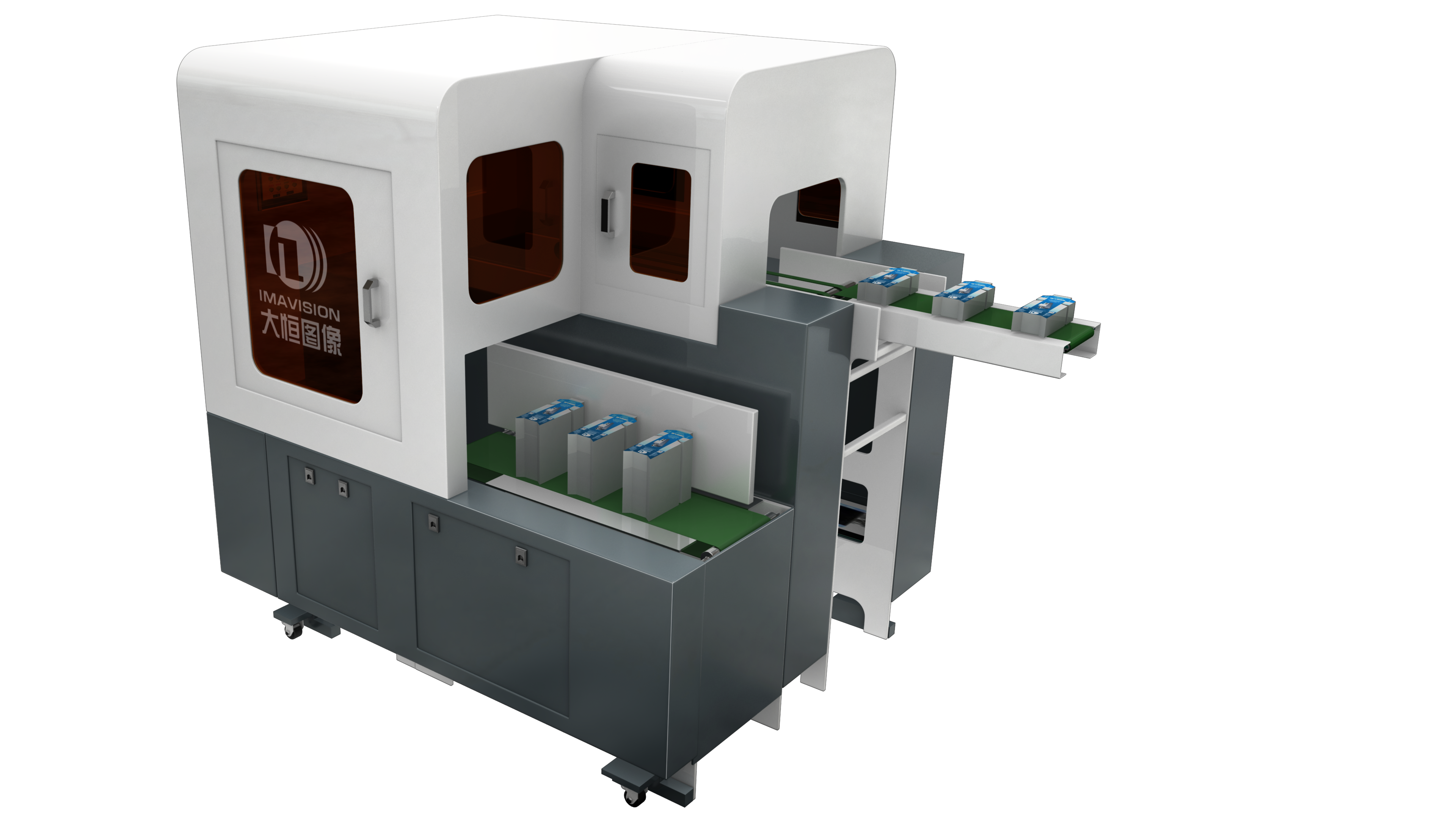

The paper storage area can hold 10 stacks of products, with 800 sheets per stack. A worker can complete paper loading in 1-2 minutes

Considering the high-speed small sheet inspection machine operating at 100,000 sheets per hour, it only takes 5 minutes for inspection. Therefore, one operator can handle the paper loading for 2 small sheet machines

The equipment automatically divides the large stack into smaller stacks, feeding them into the corner folding mechanism

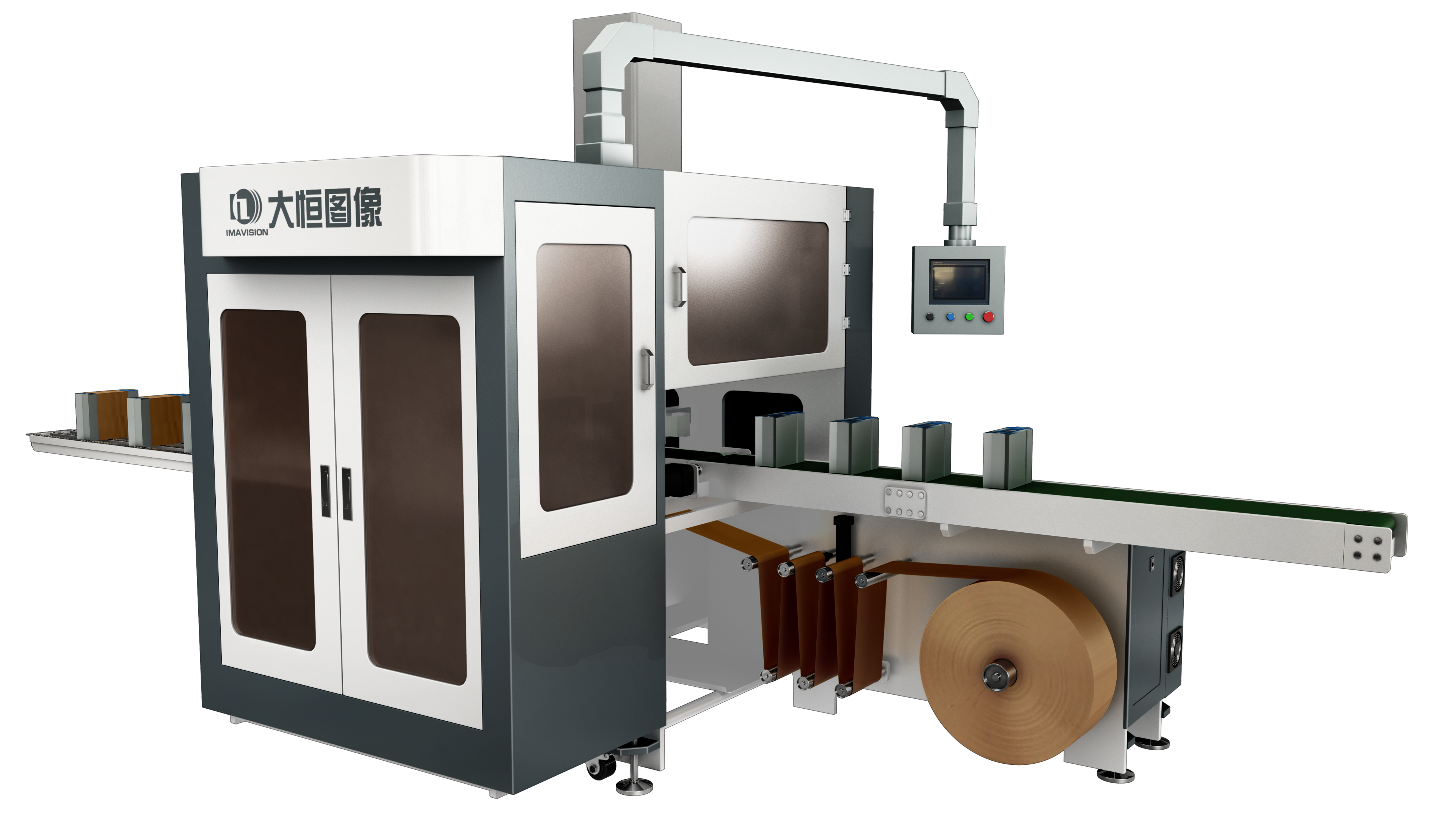

The machine has three modules: paper feeding, bundling, and stacking, with convenient bottom wheels for mobility and stability, ready for immediate use

It uses cost-effective consumables, standard roll kraft paper (less than 1200 meters), and regular adhesive tape for sealing

Minimum color variance detected is 1 △ E. Less than 0.04 △ E if inspection is repeated

Images from 12 different spectrums cover all the visible spectrums

Support for various offset printing machines, such as Heidelberg, KBA, KOMORI, MITSUBISHI

Max. inspection speed is 15000 pieces/hour, adaptable to normal printer speed

- STAR-PRINT INSPECTION MACHINE

- DH-JH550

- Carton and Corrugated Board Inspection Machine

- DH-CJP200

- DH-NHJP550/650/800

- DH-HJP 550/650/800/1100

- DH-FJ8026

- Lope 1020

- DH-CJ1020

- Automatic Dividing Machine

- Automatic Packing Machine

- DH-PCD100

- DH-Sheeton

Comprehensive Inspection

Defects Classification

Dimensional Measurement

Automatic Template Creation

AI Inspection

Automatic Packaging

Comprehensive Inspection

AI applications

Perfectly match production line speed

Auto-Focusing

Data Statistics

- Vials Inspection & Packaging All-In-One Machine

- Glass Tube Inspection Machine

Safety ring breaking

PET ring missing

Bridge breaking、Cap tilting、Cap overtop

Miscellaneous cap (color, shape)

Liquid level deviation

Label missing, Wrong label, Label flipping, Blank label

Label cutting error

Label misplacement

Label tilting

Label print error

Label damage, Corner bending

Code missing, line missing, Code blurring, repeating

Over half code missing

Zooming distortion (over 10%)

Offset, tilting (beyond set range)

Wrong code content

Miscellaneous bottle recognition (camera customization available)

Bottle mouth defect inspection (damage, link up, etc.)

Bottle bottom defect inspection (foreign matter, dirt, unfilled corner, etc.)

Side wall defect inspection (dirt, foreign matter, crack, etc.)

Residual liquid inspection

Liquid level (1mm deviation)

Suitable for glass bottles, PET bottles and cans

Suitable for products with bubbles

Suitable for containers with labels

Bottle reversal, bottle half length、Logo error

Container material inspection, separation between glass and PET

Container color inspection, color cameras needed

Can mouth ovality

Can mouth turnup

Can wall concave

Can wall coloring

Can bottom foreign matter

Production speed 6000 boxes/h

Precision 30g、Maximum weight 80Kg

Conveyor speed up to 100m/min

Weighing terminal: Mettler-Toledo dynamic weighing terminals

Sensor: Mettler-Toledo high-speed high-precision sensor

Touch screen displays product weight in real-time

Display of the quantity and weight of overweight products,eligible products and underweight products

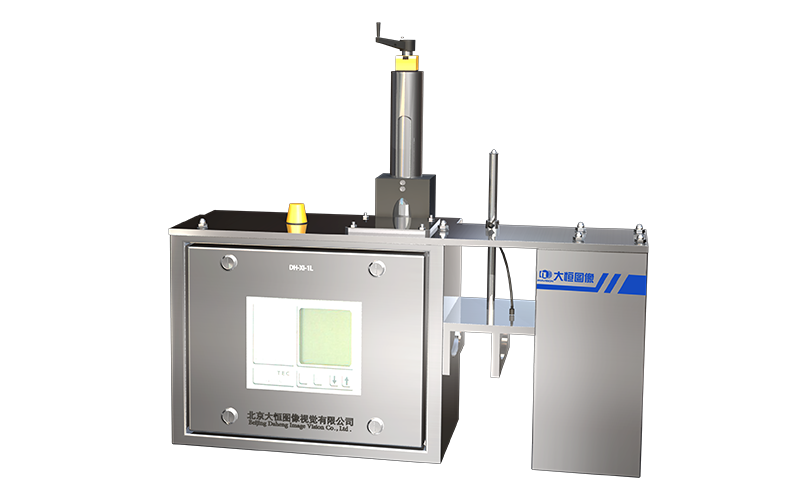

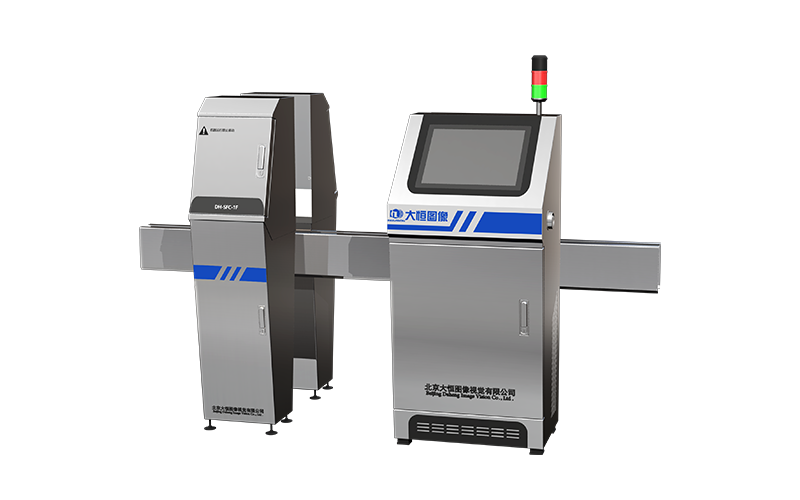

- Inspection Machine for Capping and Liquid Level

- Inspection Machine for Labels

- Inspection Machine for Code Printing

- Inspection Machine for Bottles

- X-Ray Inspection Machine for Liquid Level

- Separation Machine for Extraneous Bottles

- Inspection Machine for Cans

- Inspection Machine for Box Fullness

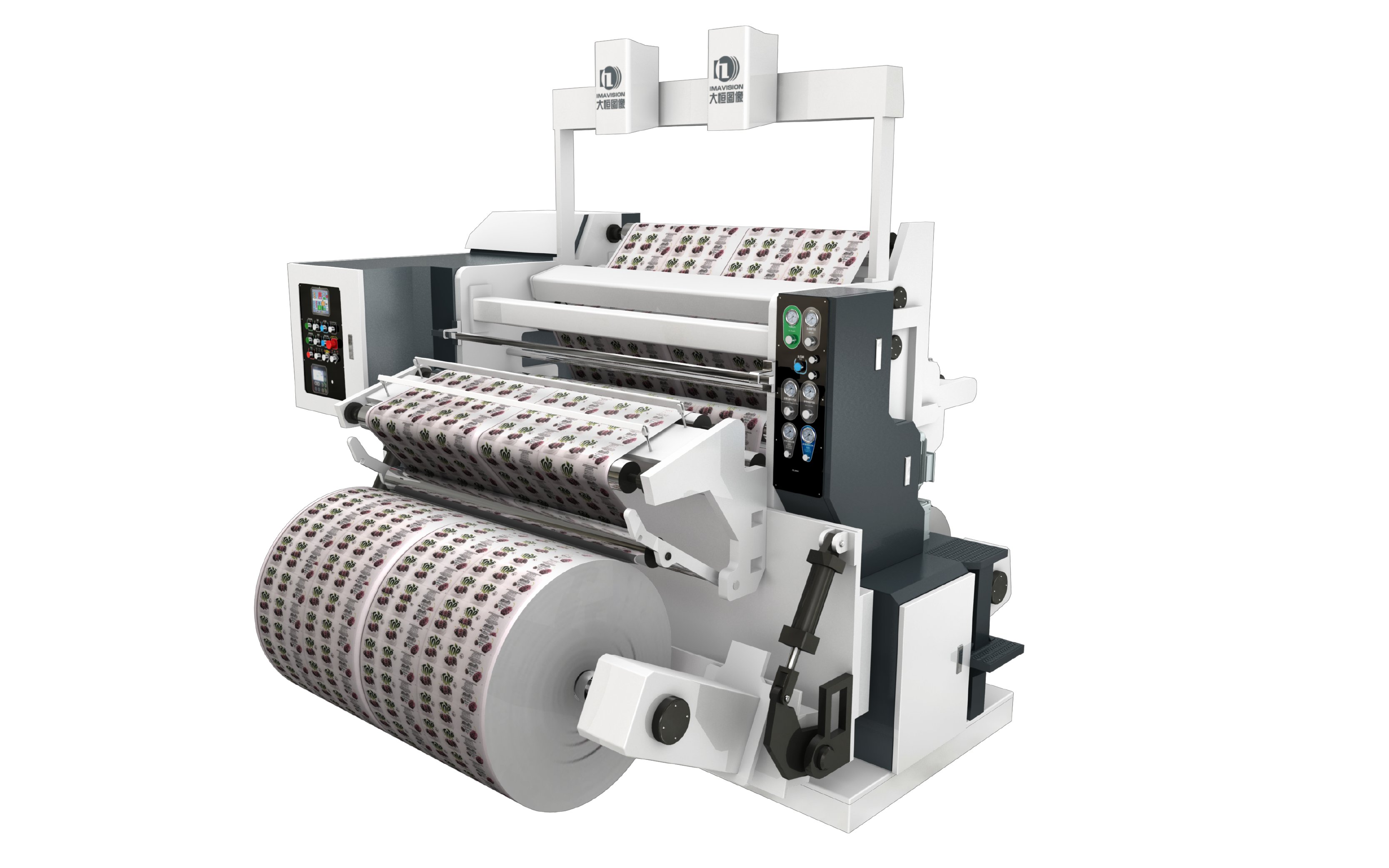

Two inspection modes:roll-to-roll、roll-to-sheet

Reject defective sheet, and good sheets collect by stacks

Algorithm can extract different color areas, and inspect each la yer automatically

Inspect sequence code, inkjet code, and related code

Record and generate data files for each slitting rolls

Generate statistic report

Equip reviewing machine as optional

Equip label sticker, ink-jet marker as optional marking devices

Variable Code: Inspect print quality and variable code.

Doctor Blade Streak Inspection: Specially optimized streak inspection algorithm for higher efficiency.

Color Variance Monitor: Display the trend of color variance change through real-time curves in interface.

Product Period Monitor: Inspect product period to detect material tensile deformation.

Inspecting varnish missing, deviation

Inspecting lamination bubble, wrinkles

The most powerful variable data inspection

Efficient print quality inspection

- Roll-to-sheet Inspection Machine

- Label Inspection Rewinding Machine

- Flexible Package Print Quality Inspection System

- Double-workstation Label Inspection Rewinding Machine

-

Printing Inspection

Printing Inspection- The printing industry encompasses a range of processes where potential quality issues may arise. Employing 100% quality testing equipment during the printing process is an efficient method to guarantee print quality, save costs, and enhance production capacity. With decades of experience in the field of printing inspection, Daheng image has introduced a range of ready-to-use printing inspection systems and machines tailored for various processes.

Get more

-

Bottle Inspection

Bottle Inspection- Glass bottles are widely used in the packaging of biopharmaceuticals, food and beverages, and daily chemical products, closely intertwined with people's lives. Therefore, the bottle manufacturing industry is a field with high demands for quality control and inspection. Daheng image has developed a series of empty bottle quality inspection machines that incorporate state-of-the-art machine vision technology.

Get more

-

Pharmacy & Canning Inspection

Pharmacy & Canning Inspection- In the field of pharmaceutical manufacturing, there are various forms of medications and related production and packaging processes. Within these processes, there are potential quality defects in pharmaceuticals, directly impacting the safety of patients' medication.

Get more

-

Label Inspection

Label Inspection- In response to potential issues that may arise with labels and variable data during the printing process, Daheng Image draws upon over a decade of technical expertise accumulated in the banknote and ticketing industries, We have developed a series of products and solutions tailored to meet the needs of our customers, particularly in the detection of variable information such as numbers, barcodes

Get more

-

- Beijing Headquarters

-

-

-

-

-

-

-

-

-

Beijing Daheng Image Vision Co.,Ltd.

-

0Foundation 1991

-

07 Offices

-

0 +Projects More Than

500 Regions