Your Current Position: Home - Products - Printing Inspection - Carton and Corrugated Board Inspection Machine

Printing Inspection

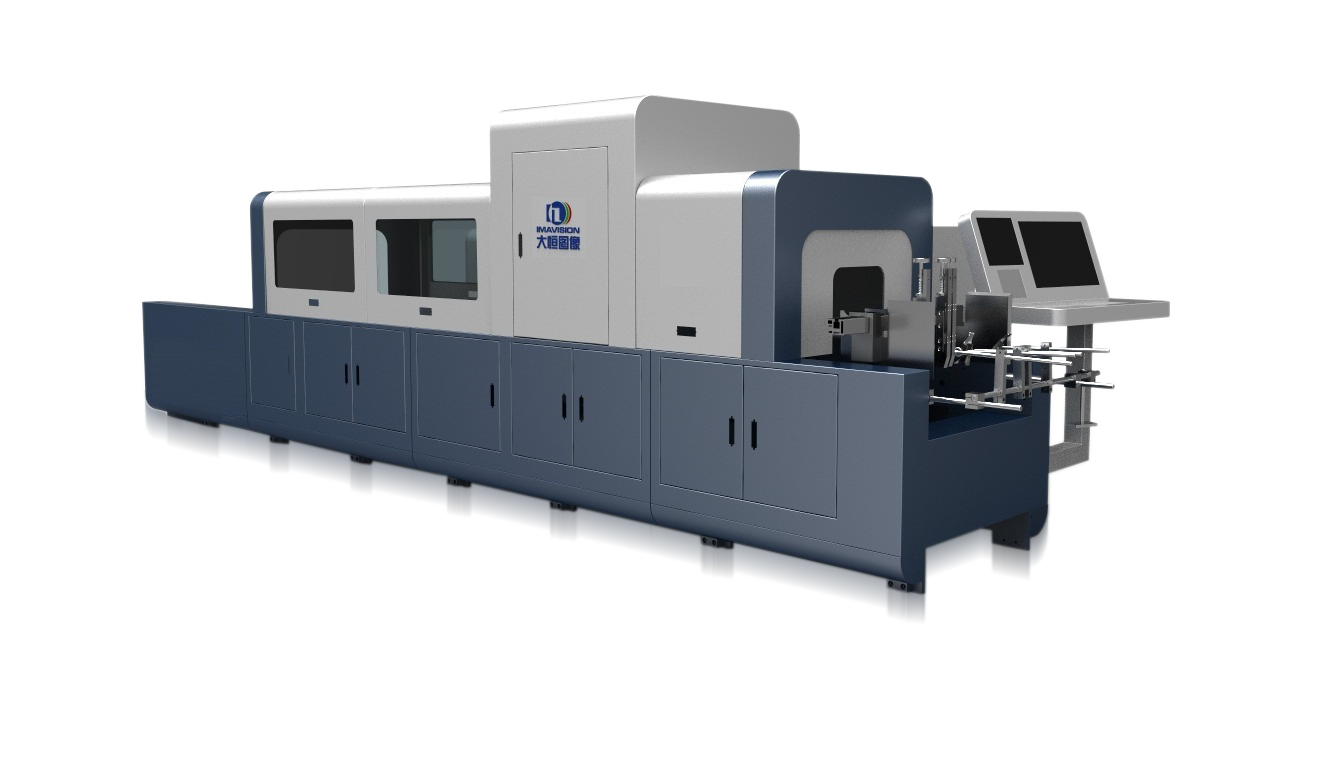

Carton and Corrugated Board Inspection Machine

The machine is commonly used to inspected surface quality for corrugated board and printing sheet of carton board after die-cuting

- Product Features

-

Replaces manual labor with 24-hour high-speed work without fatigue and allows for rapid switching between inspected products

Multi-station design for comprehensive print process inspection, customizable for special process checks

Quick modeling, with modeling taking only 3 minutes

Equipped with a dual-reject structure to meet the paper path requirements for both corrugated board and cardboard on the same platform

Products Overview

Applications

Corrugated board types: B、E、F、G;Carton board

Specifications

| Item | 650 | 800 | 1100 |

|---|---|---|---|

| Inspection station(standard) | foil stamping(4K color camera) gravour varnish(8K mono camera) | ||

| Inspected defects | spot、missing print、streak、foil stamp missing、wrinkle、scratch、die-cut deviation、 varnish missing etc. | ||

| Max. size (WxL) (mm) | 650mm×500 | 800mm×500 | 1100mm×800 |

| Min. size (WxH) (mm) | 250×250 | 250×250 | 250×250 |

| Paper quality (corrugated board) | B、E、F、G | B、E、F、G | B、E、F、G |

| Paper quality (carton board) | 200g-500g/m² | 200g-500g/m² | 200g-500g/m² |

| Max. delivery speed | 230m/min | 230m/min | 230m/min |

| Inspected speed(corrugated board) | 20000 pcs/h | 20000 pcs/h | 20000 pcs/h |

| Minimum defect size (as a point) | 0.2mm²(contrast≧20) | 0.15mm²(contrast≧20) | 0.15mm²(contrast≧20) |

| Minimum defect size (as a line) | W≧0.2mm;L≧5mm(contrast≧20) | W≧0.15mm;L≧5mm(contrast≧20) | W≧0.15mm;L≧5mm(contrast≧20) |

| Color variance | △E≧3 | △E≧3 | △E≧3 |

| registration | ±0.2mm | ±0.15mm | ±0.15mm |

| Accepted products handling | shingle stream module, direct output | shingle stream module, direct output | shingle stream module, lateral output |

| Rejected products handling(Corrugated) | shingle stream module, lateral output | shingle stream module, lateral output | shingle stream module, lateral output |

| Rejected products handling(Carton) | shingle stream module, direct output | shingle stream module, direct output | shingle stream module, direct output |

| Floor space LxWxH(mm) | 10600×2830×1880 | 10600×2830×1880 | 11800×3160×1880 |

| Weight | 6500kg | 7000kg | 7500kg |

| Total power | 25kW | 25kW | 29kW |

CONSULTATION

15F Daheng Science & Technology Tower, No.3 Suzhou Str., Haidian District, Beijing China

+8610-82362836

E-mail: consult@daheng-imaging.com