Automatically tidy up disorganized vials serving for inspection

Efficient vial inspection achieving by template setting

Automatically pack qualified ampoules into boxes

High efficiency, High repeatability, High reliability

- Product Features

-

Identify- Remove-Reorganize process:Automatically identify and remove broken vials;Rotate disorganized vials into the same direction before formal inspection

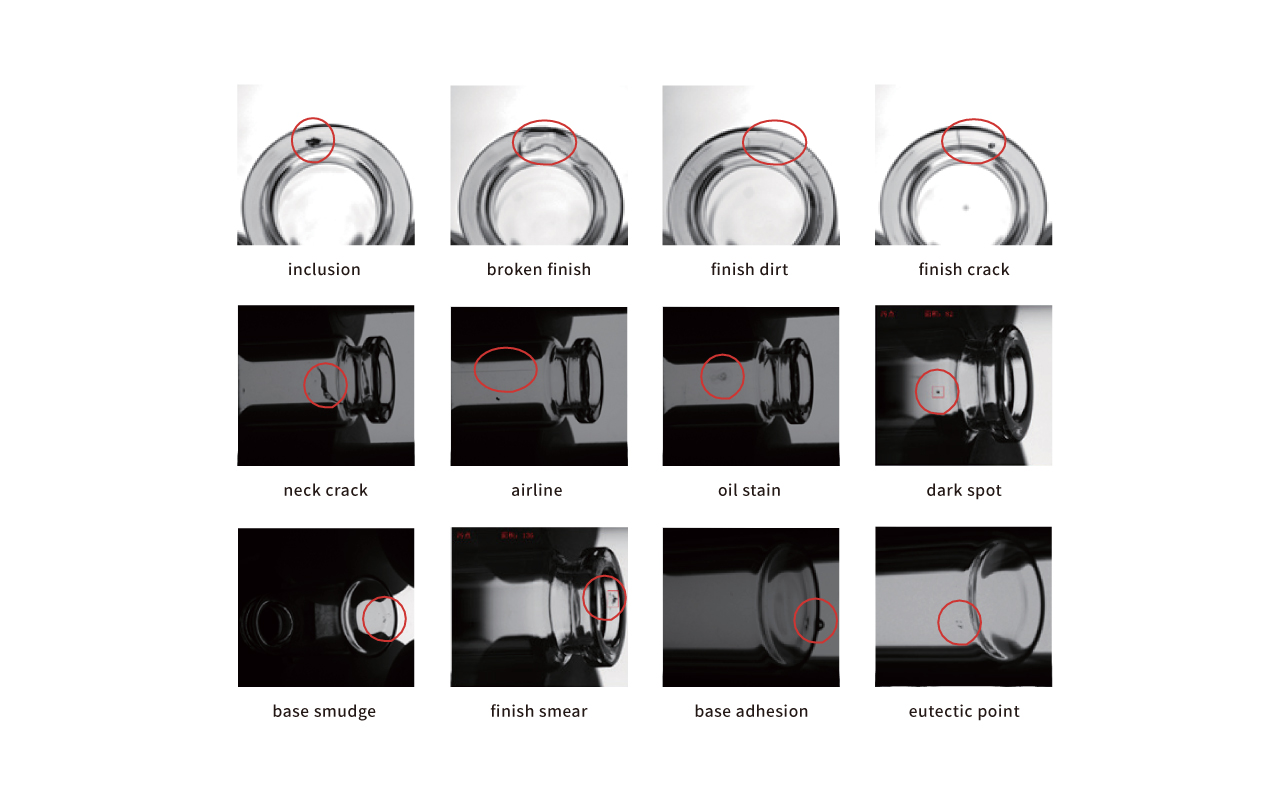

Comprehensive Inspection: Evenly rotate every vial 360 degrees, 5 cameras continuously shoot vial pictures from every angle to analyze defects

Defects Classification:Classify defects intelligently,timely output production report in shifts,provide data support for quality management system in the meantime

Dimensional Measurement:Automatically measure every single vial based on predetermined upper and lower size limilits;Realtimely display tendency chart of dimensions

Automatic Template Creation:Algorithm automatically generate positioning and inspection regions while modeling

Convenient Packing:Customized box package in round numbers

Flexible Configuration:Flexibly connect with robotic feeding system or feeding elevator

Cold-end Vial Inspection Machine

| Item | Specification |

|---|---|

| Color of Vial | Any color |

| Volume of Vial | 2ml - 30 ml |

| Inspection speed | 65 bottle/min |

| Power | AC220V,2.6KW |

Inspection Precision | ±0.02mm |

| Inspection items | *Body defects: bubbles, impurity, ripples, airlines, stripes, adhesions, knots, cracks, abrasion, scratches, visible grease mark, fingerprint, etc. *Base defects: uneven base, adhesion, basal spine, center deviation, etc. *Shoulder defects: sloping shoulder, crooked bottle *Finish defects: incomplete finish, split finish, burr, overpressed edge, wire edge, etc. *Dimensional measurements: height, outer diameter of body and finish, inner diameter of finish, finish height, outer diameter of neck, etc. |

Optional Module:

Inner diameter of finish inspection module(DH-KNJXT-1)

Performance Indicator:

Measure maximum and minimun inner diameter of finish,automatically calculate ovality;

Some certain types of inspection machines could get more accurate data by analysing multiple pictures

Defects

Previous: Hot End Inspection Machine