Realtimely inspect & measure glass tube,remove unqualified tube in the meantime, provide data to support full-automatic process.

- Product Features

-

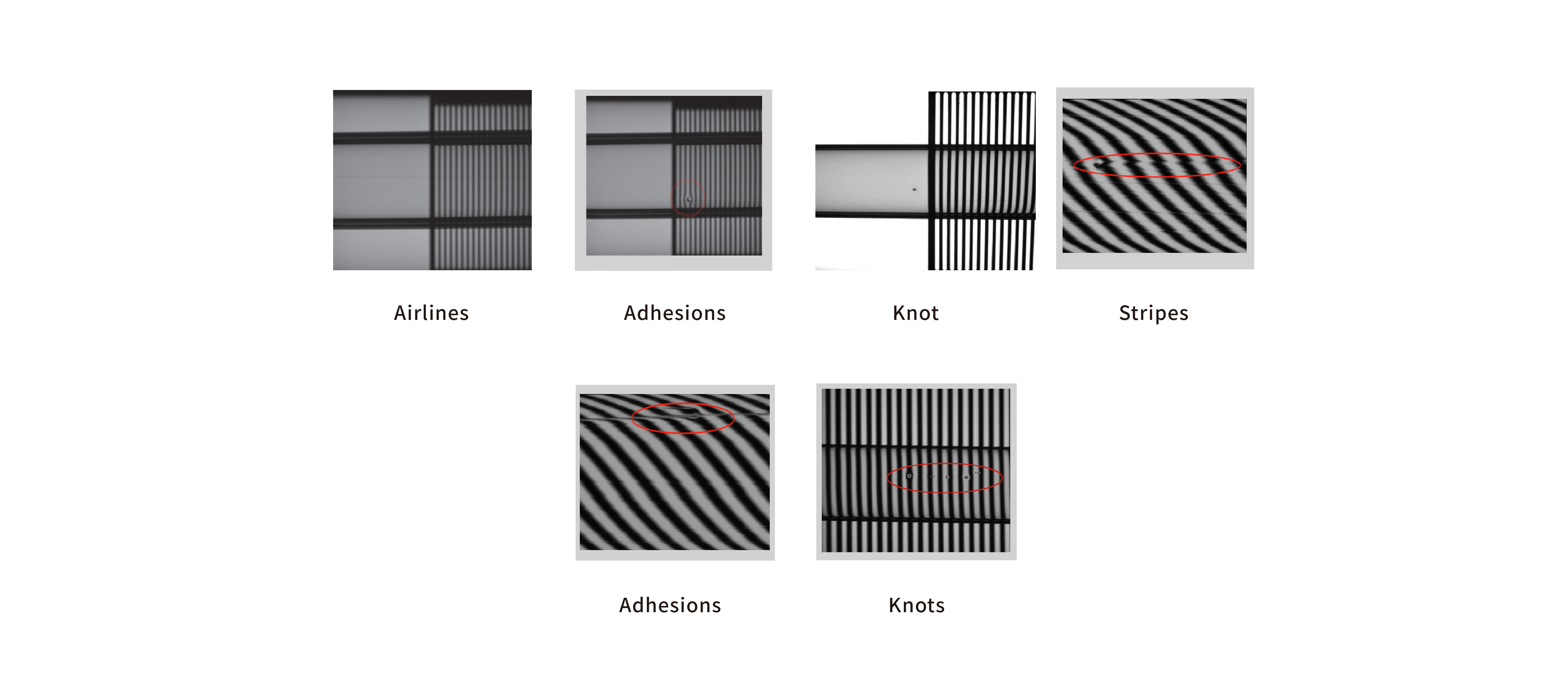

Comprehensive Inspection: 1)Evenly rotate every tube 360 degrees, 3 cameras continuously shoot tube photos from every angle to inspect defects, 2 cameras measure outer diameter &ovality; 2)Optional function: Add 1-2 cameras to measure tube thickness

AI applications:Deeply learn & inspect knots/stripes/adhesion, no need to train inspection system if change different sizes of tubes

Perfectly match production line speed:Automatically adjust inspection parameters by calculating tube production line speed, in order to precisely remove unqualified tube

Auto-Focusing:Automatically identify & adjust tube location if change different sizes of tubes in order to ensure inspection accuracy

Data Statistics:Realtimely inspect&display locations of defects and analyze precisely, output production report in shifts

Parameters

| Items | Specification |

|---|---|

| Color of tube | Any color |

Diameters of tube | 10ml - 32ml |

| Inspection speed | 230 meters/min |

Remove Unqualified Tube Mode | Relay of Inspection system control turnover panel to remove |

Inspection Precision | Airlines/Knots: 0.05mm Adhesion/Stripe: 1mm Outer Diamete/Thicknessr: 0.01mm |

Inspection Items | Airlines/Knots/Stripes/Adhesions Outer diameter/Ovality/Thickness |

Defects

Previous: Ampoule Inspection Machine