- Product Features

-

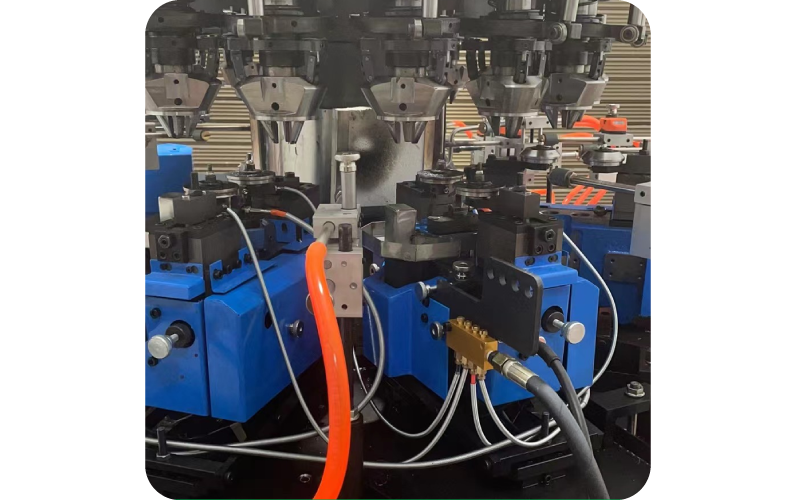

High-precision positioning: 1)Using advanced digital robotic reduction drive system to control vial-moving process which refers to vials finish&neck forming(A part:16 work-stations) and vial bottom forming(B part:10 work-stations) ;Accurately grab vials using flexible three-claw clips(adjustment range: 14-30 degrees)

Full-server vial-forming platform: 1)Greatly improved vial quality by independent R&D forming platform,like decrease dark spots when forming vial finishes achieved by ultra-long life mould core and cooling fuel injection system ; 2)Flexibly set up different vial finish size on touch screen, without adjust mechanical part

Excellent hydrolytic resistance: Improved hydrolytic resistance by 0.2 using advanced technology compared with similar vial-making machines

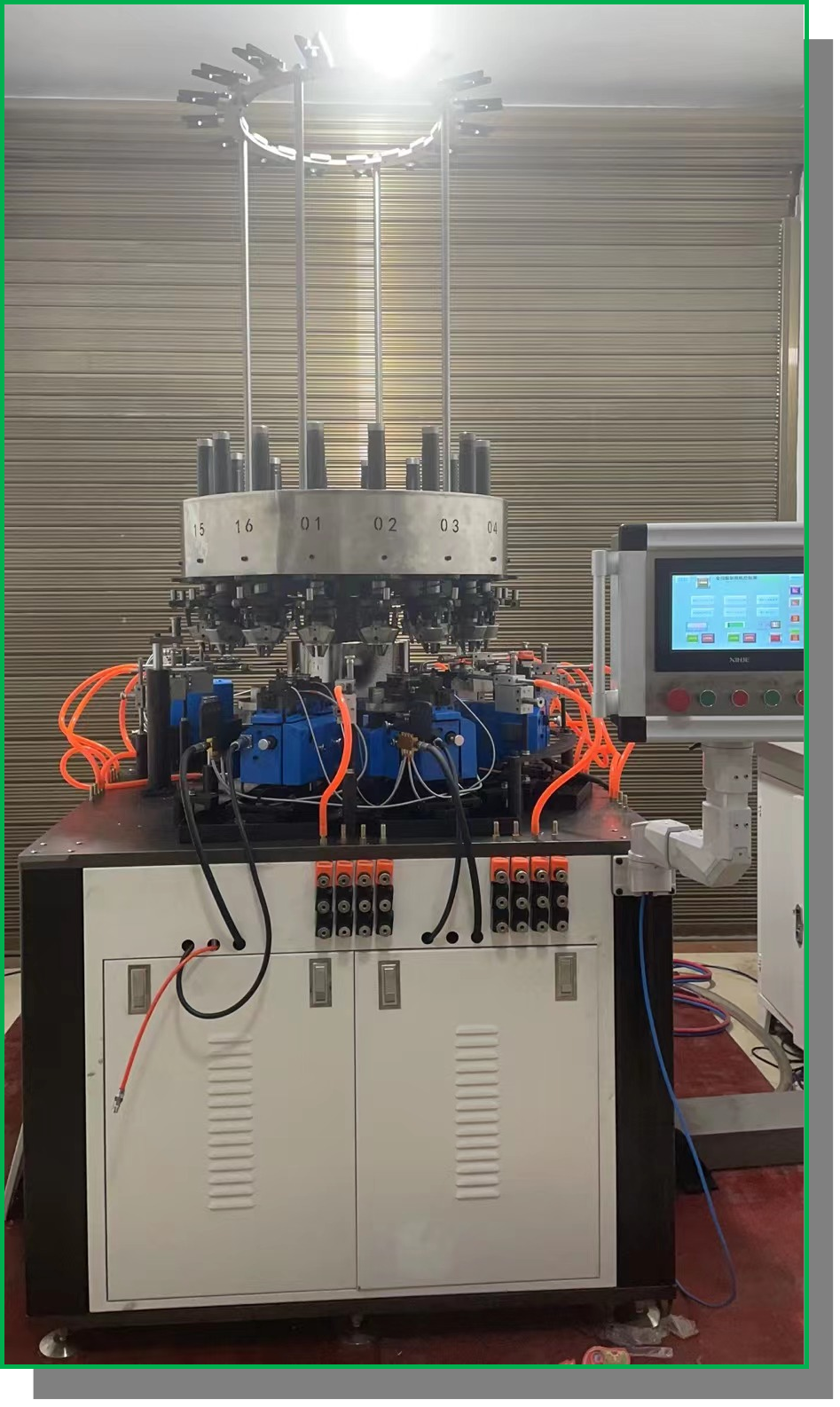

Vertical full-server vial-making machine

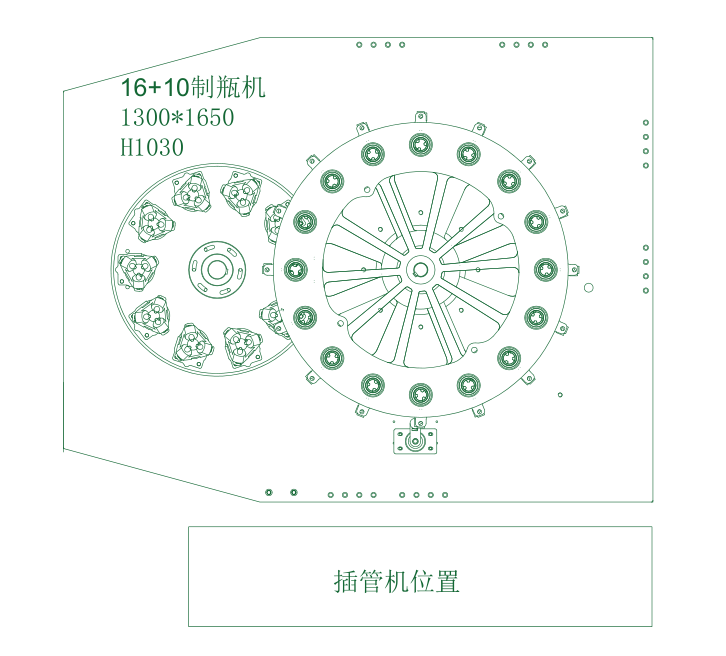

The whole machine:

A part(16 work-stations,vials finish&neck forming):You can 350°rotate touch screen cabinet.Every vial drops smoothly is controlled by robotic manipulator.We use 3 digital forming platforms to shape vials, you can change different parameters with one-click.

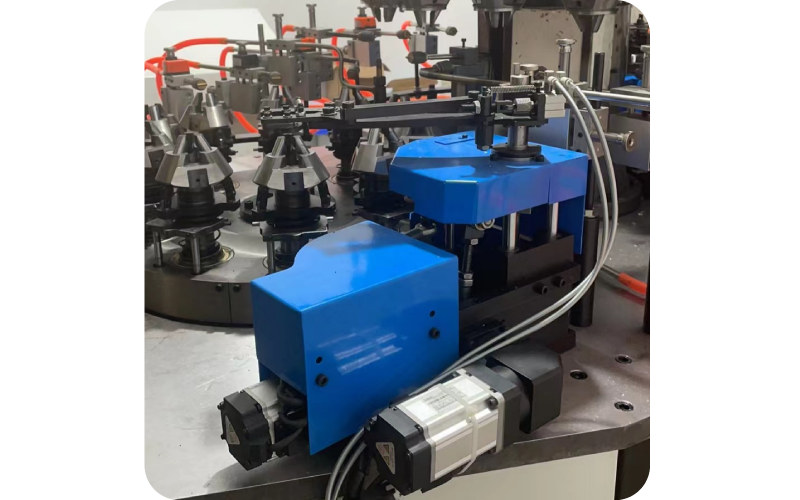

B part(10 work-stations,vial bottom forming):Vial-holding manipulator we refer to Germancreative design, aim to grab vials quickly and steadily.

Parameters

| Items | Parameters |

|---|---|

Vial Specifications | Height:25-80mm Outer diameter of neck:φ12-24mm |

Maximum speed | 36 vials/min |

Energy Consumption | Electric consumption≤1.75kilowatt-hours Natural gas consumption≤2.0m³/hour |

Control Mode | Ether CAT servodrive; Convenient maintenance |

Forming platform | Unique patented forming platform; Enhance quality in terms of decreasing dark spots on vial finish |

Lube-cooling hydraulic system | With Independent IP |

Machine Layout

Previous: Vials Automatic Production Line