Efficient vial inspection achieving by template setting,automatically pack qualified vials into boxes.

High efficiency, High repeatability, High reliability.

- Product Features

-

Comprehensive Inspection: Evenly rotate every vial 360 degrees, 7 cameras continuously shoot vial pictures from every angle to analyze defects

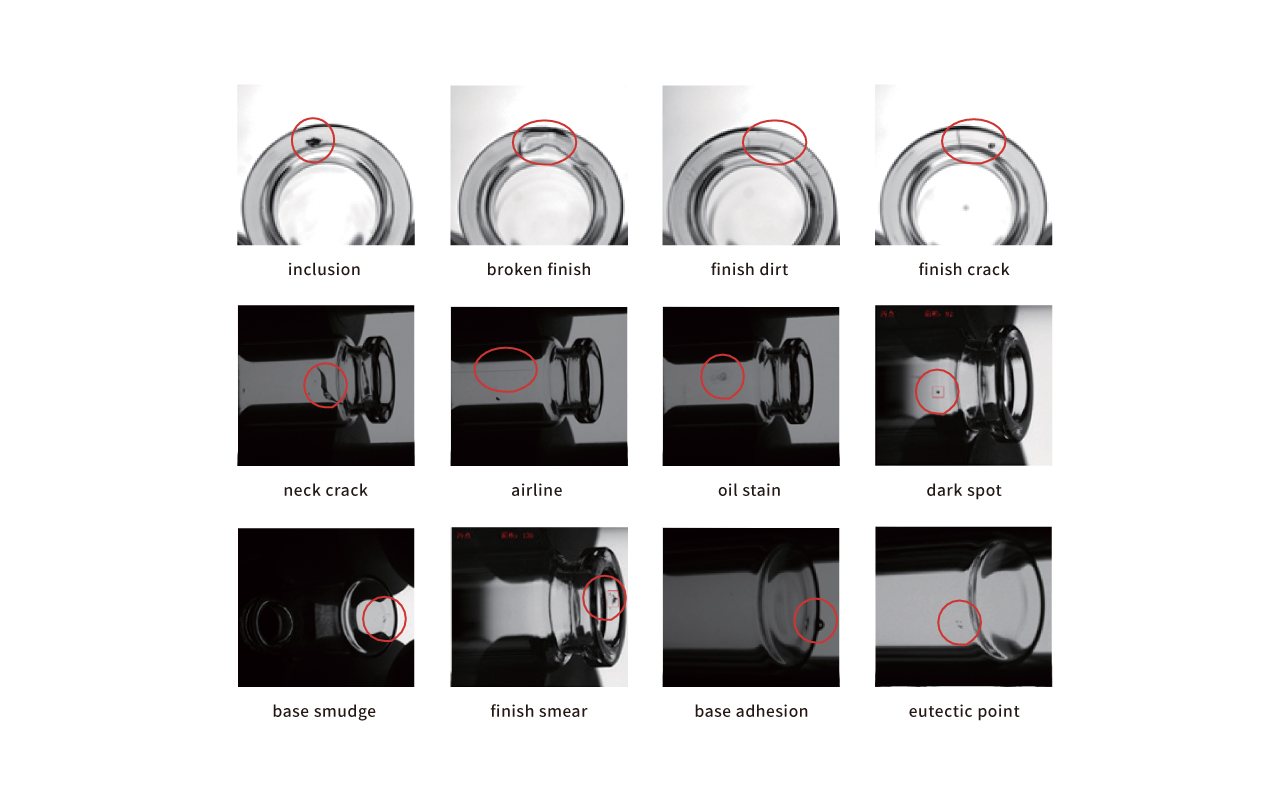

Defects Classification:Classify defects intelligently,timely output production report in shifts,provide data support for quality management system in the meantime

Dimensional Measurement:Automatically measure every single vial based on predetermined upper and lower size limits;Realtimely display tendency chart of dimensions

Automatic Template Creation:Algorithm automatically generate positioning and inspection regions while modeling

AI Inspection:Optional module:Using deep learnning technology to inspect vial finish defects, efficiently make up the shortcomings of traditional algorithm, such as influence of irregular shadow

Automatic Packaging:1)Automatically pack qualified ampules into boxes,adapt to vials with specifications of outer diameter (φ13-φ32) and height (30-75mm);2)Suitable packaging box dimensions: length: 0-450mm, width: 200-500mm;3)Boxes storage capable quantity:4 boxes

Parameters

| Items | Specifications |

|---|---|

| Color of vial | Any color |

Volumes of Vial | 2 ml - 32 ml |

| Inspection speed | 60 bottles/min |

Power | AC220V, 4KW |

Inspection Precision | ±0.02mm |

Inspection Items | *Body defects: bubbles, impurity, ripples, airlines, stripes, adhesions, knots, cracks, abrasion, scratches, visible grease mark, fingerprint, etc. *Base defects: uneven base, adhesion, basal spine, center deviation, etc. *Shoulder defects: sloping shoulder, crooked bottle *Finish defects: incomplete finish, split finish, burr, overpressed edge, wire edge, etc. *Dimensional measurements:height, outer diameter of body and finish, inner diameter of finish, finish height, outer diameter of neck, shoulder R, etc. |

Defects

Previous: Cold-end Vial Inspection Machine