- Product Features

-

Variable Code: Inspect print quality and variable code.

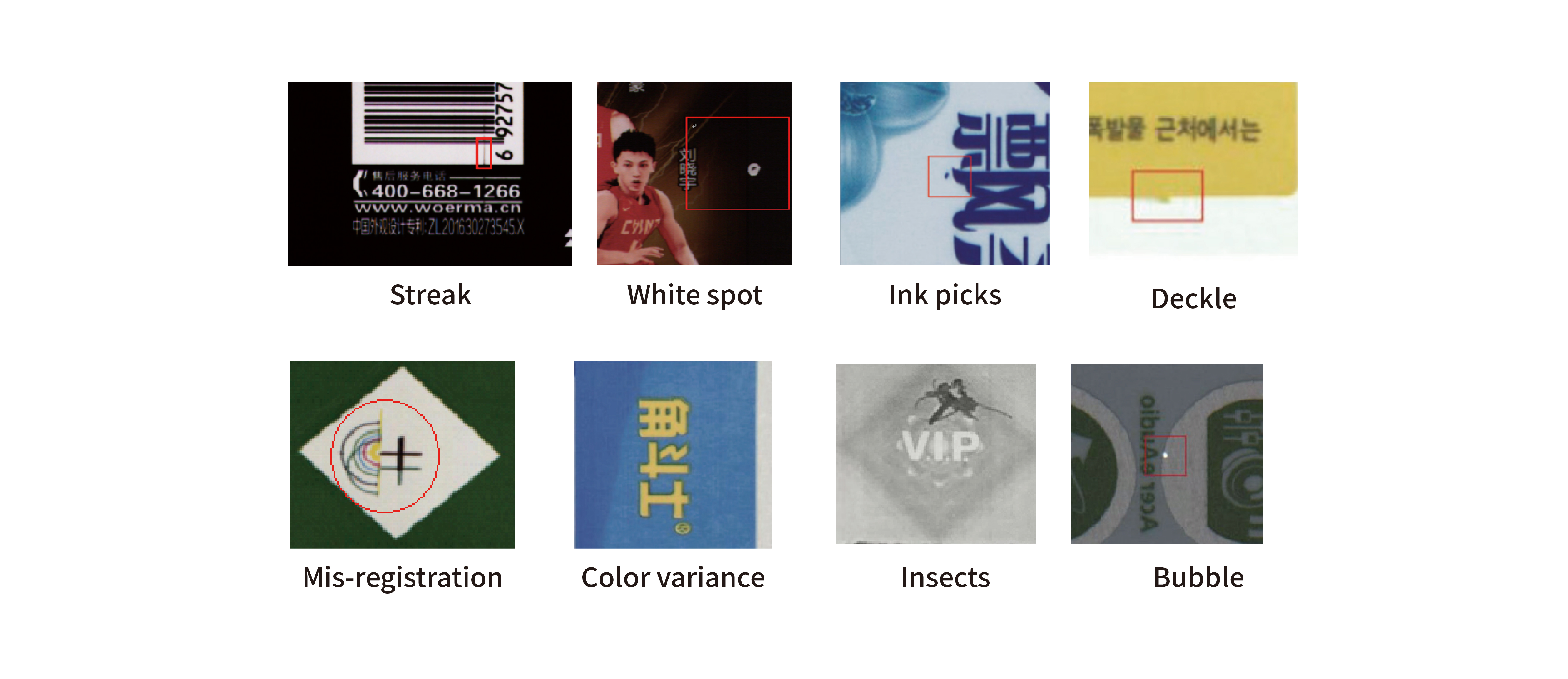

Doctor Blade Streak Inspection: Specially optimized streak inspection algorithm for higher efficiency.

Color Variance Monitor: Display the trend of color variance change through real-time curves in interface.

Product Period Monitor: Inspect product period to detect material tensile deformation.

Real-time Monitor: Display grabbed image in real-time.

Defect Classification: Automatically classify defects through AI algorithm to focus on specific defects.

Generate PDF Report: Generate PDF report after the inspection is completed.

Front and Back Inspection: Support to customize front and back inspection.

Defect Handling: Labelling machine is an optional device for inline inspection.

Reviewing System: Inline inspection system can inspect whole roll and store the position of the defects. After the inspection is completed, the data of the roll can be loaded into reviewing machine through LAN. The reviewing machine will automatically stop on defect position for handling.

Specifications

| Item | Parameter | |

|---|---|---|

Web Width | 600 mm-1500 mm | |

Max. Inspection Speed | 400 m/min | |

Defect | Missing print, Spots, Ink picks, Streak, Mackle, Mis-registration, Color variance, Deckle, Wrinkle, Bubble, Hole, Scratches, Water mark, Deformation, Insect. | |

Min. Defect Size | In high contrast: 0.2 m㎡ In low contrast: 0.4 m㎡ | |

Min. Streak Size | Width≥0.1 mm Length≥5 mm | |

Color Variance | △E≥3 | |

Mis-registration | ±0.1 mm | |

Defect Images

Site photos