- Product Features

-

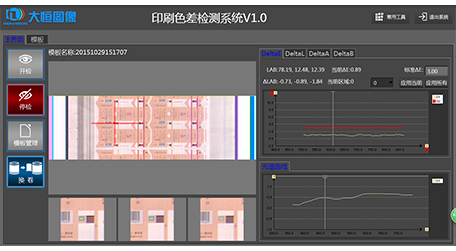

Minimum color variance detected is 1 △ E. Less than 0.04 △ E if inspection is repeated

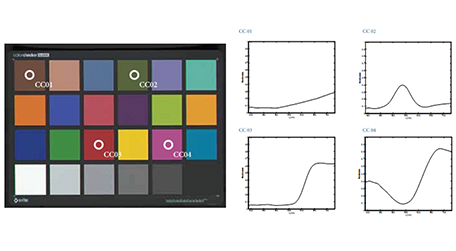

Images from 12 different spectrums cover all the visible spectrums

The system grabs images of the printing products and outputs the color variances and local spectrum images in real time, assists the quality control of production

Able to output curves of spectrums, color variances and LAB values

Applications

Real-time color inspection for printing products, continuously computes color changes and alarms when the color variances become unacceptable.

Compatibility

Gravure printing machines, offset printing machines, flexo printing machines and other printing equipment.

Inspection precision

Minimum color variance detected is 1 △ E. Less than 0.04 △ E if inspection is repeated.

Features

■ Image resolution 0.25mm, field of view (customizable) 875mm, maximum speed 330m/min

■ Average measurement error 0.9-1.1 △ E

■ The data was acquired by testing on 100 HKS color cards and compared with four kinds of handheld gadgets on the market

■ The charts on the right are the curves of spectrums output from DH-PCD100 compared with the practical curves

■ Precision less than 0.04 △ E if inspection is repeated

■ The variance of the average on 10 measurements of the same color is less than 0.04 △ E

Previous: Rewinding Online Inspection System

Next: Stack Robot