- Product Features

-

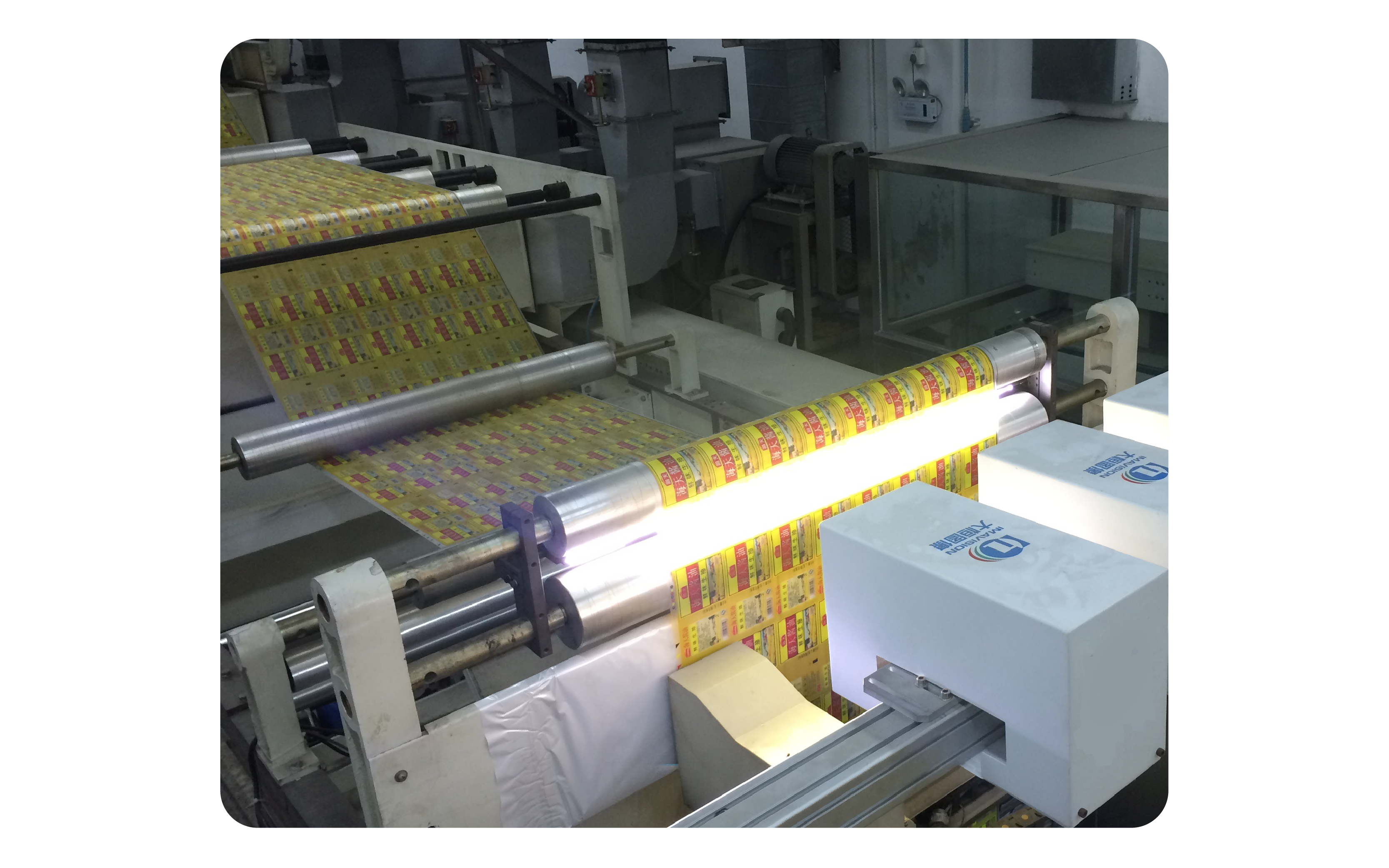

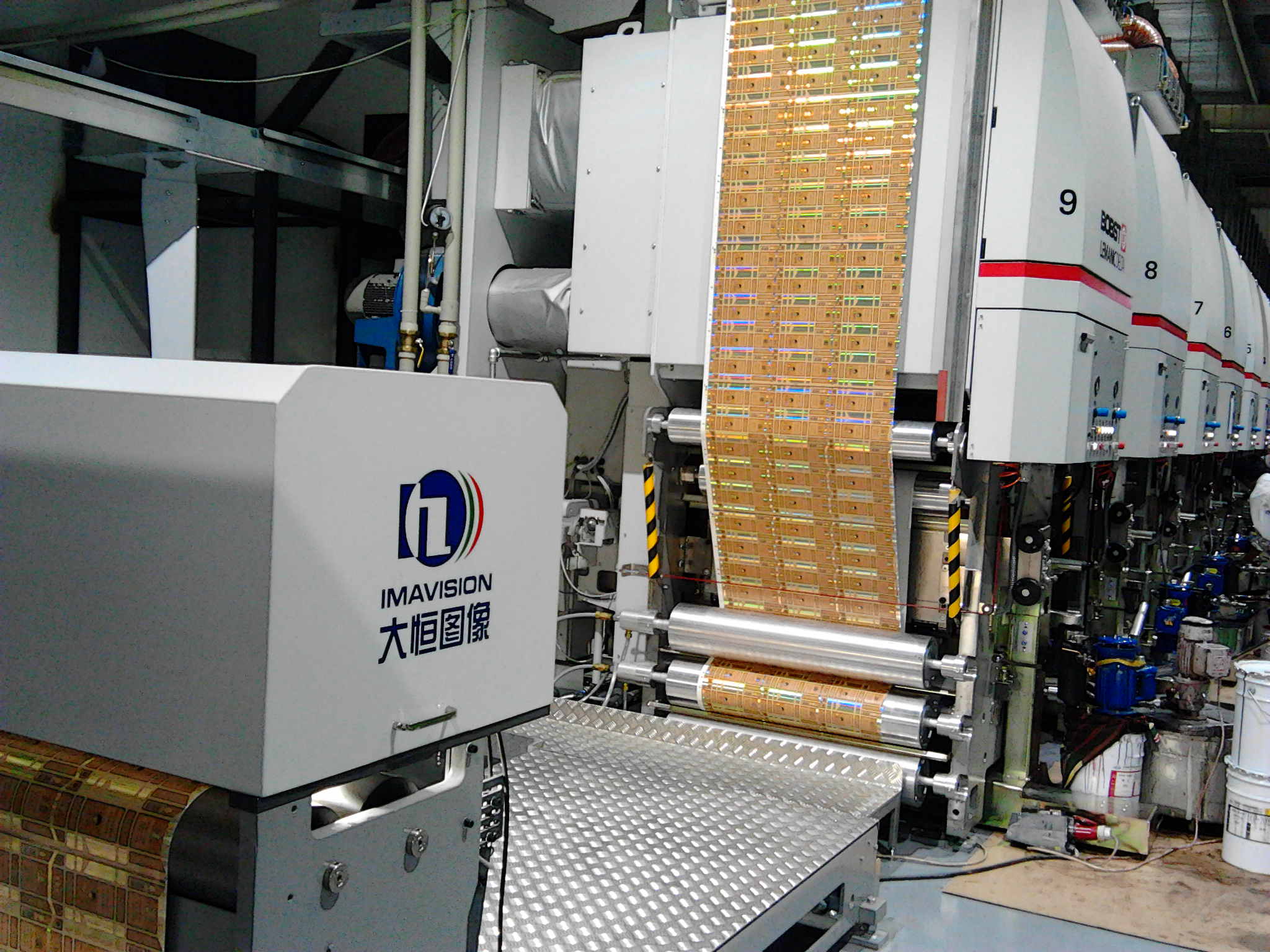

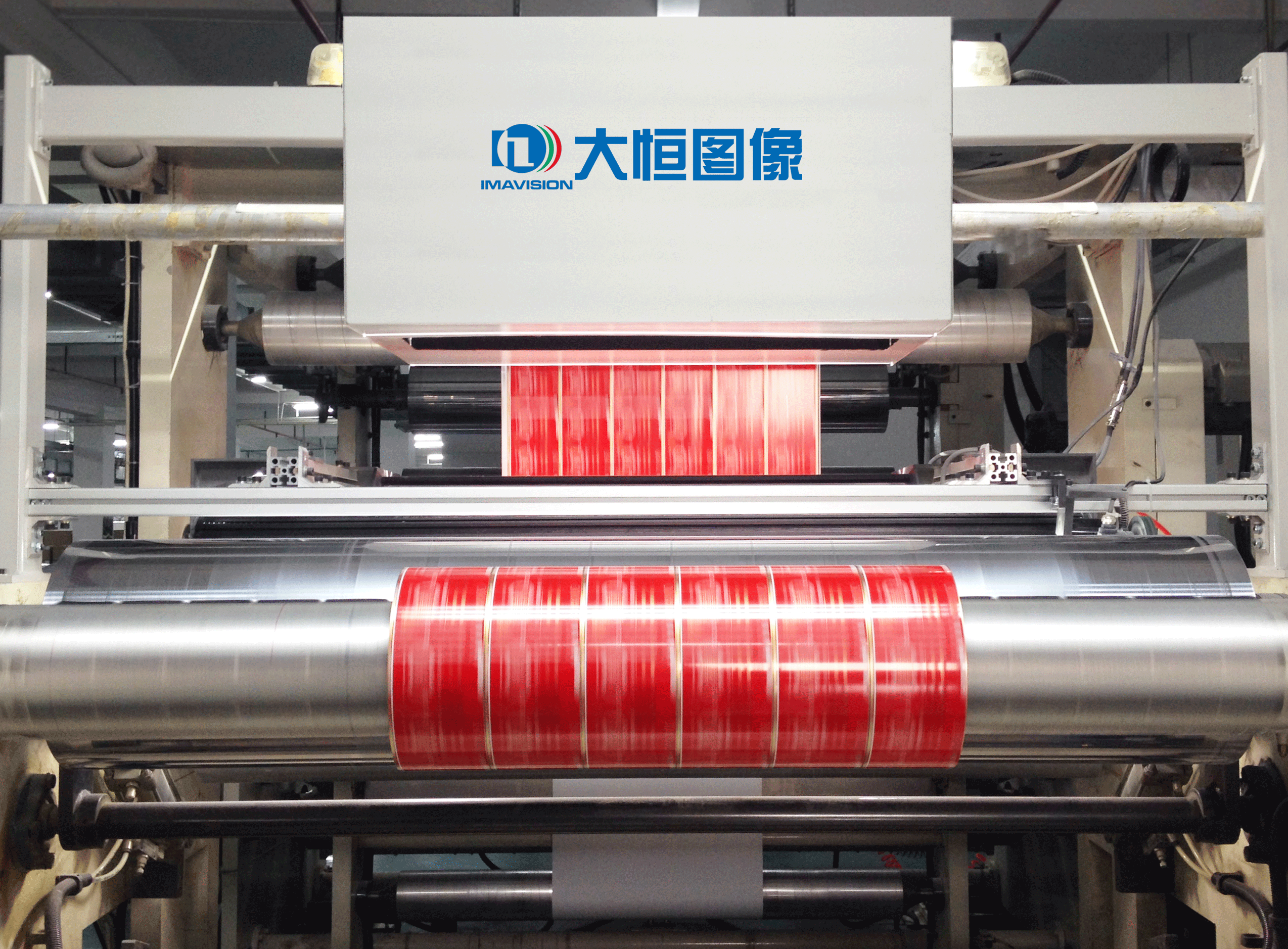

Detects continuous defects such as wire breaks, ink pulls, color variations, and misregistration promptly, providing real-time alerts and adjustments to reduce waste and production costs

Achieves a maximum inspection speed of 600m/min, enabling 24/7 uninterrupted inspection and reducing the labor intensity of manual quality control

Features an independent defect management system, offering remote office defect viewing to assist in post-process reviews and rechecks

Enables rapid modeling to reduce manual intervention and enhance production efficiency

Provides high-quality real-time full-width image monitoring

Specifications

| Item | Label | Cigarette packs | Tipping paper/Lining paper | Flexible packs/Tetra packs |

| Applied equipment | Flexographic press, gravure press, letterpress machine, offset press, coating machine, laminating machine, die-cutting machine, foil stamping machine, slitting machine, rewinder, and other roll-to-roll printing and processing equipment. | |||

| Applied material | Chrome paper、Ivory board、Gold and silver cardboard、Laser paper、Tipping paper、Printing and processing materials for roll products like plastic films. | |||

| Inspected defects | ink streaks, color variance, ink dots, misprints, insects, misalignment, etc. | |||

| Inspected width | 330/420/520 | 650/820 | 650/900/1200 | 1020/1200/1500 |

| Standard configuration | 4k color camera X 1 | 4k color camera X 2 | 4k color camera X 2 | 4k color camera X 2 |

| Max. inspected speed | 200 m/min | 300 m/min | 400 m/min | 600 m/min |

| Minimum defect size (as a point) | 0.1mm² | 0.1mm² | 0.1mm² | 0.3mm² |

| Minimum defect size (as a line) | 0.1mm | 0.1mm | 0.15mm | 0.18mm |

| Min. color variance | △E≥3 | △E≥3 | △E≥3 | △E≥3 |

| Multispectral CV(Optional) | — | △E≥1 | — | △E≥1 |

| Registration | ±0.1mm | ±0.1mm | ±0.1mm | ±0.3mm |

| Handling of defects(Standard) | ● real-time alerts ● Remote defect viewing and management ● Printing defect statistical reports | |||

| handling of defects(Optional) | ● Serious defect labeling machine ● Defect inkjet printer ● Defect product laser perforating machine ● Defect reinspection machine, downtime accuracy ±20mm | |||

| Opposite workstation(Optional) | Detection of defects with 3D relief effects such as embossing, varnish, etc. | |||

Previous: Variable Data Inspection System

Next: DH-PCD100