Printing Inspection

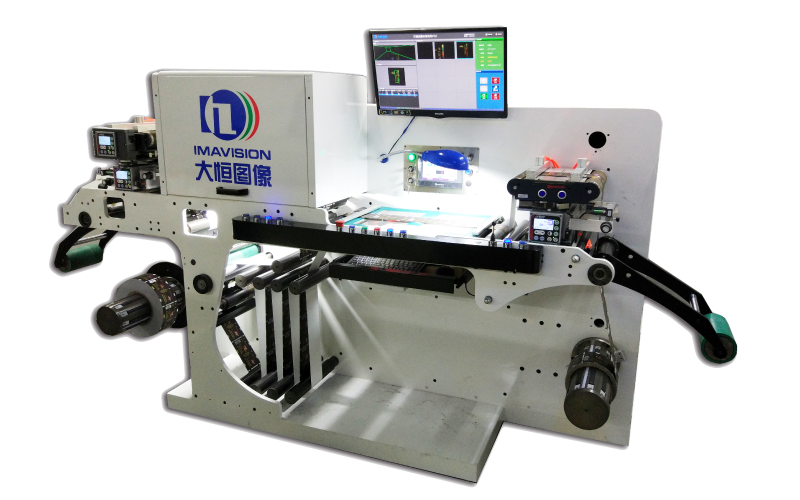

DH-FJ8026

Reeller, narrow-web print inspection slitting & rewinding machine, is used to inspect a variety of rotary cigarette, pharmaceutical, cosmetic, food, daily consuming, and FMCG labels and packages and able to slit into multiple rolls after inspection.

- Product Features

-

Support for setting up master within 3~5 min for quick inspection

Organized interface displays defect in accordance with label inspection feature and operation habit

Support for inspecting the print defects, and multiple variable data at the same time

Various defect handling methods: sound and light alert, machine stop as standard and defect review machine as option

Support to store inspection record into database in real time for traceability afterwards

Products Overview

Specifications

| Item | DH-FJ8026 |

|---|---|

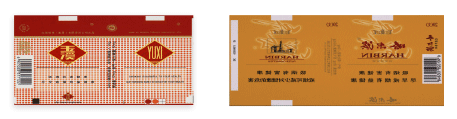

| Mainly suitable packages | Soft cigarette packages |

| Max. inspection width | 200 mm |

| Material thickness | 0.08-0.4 mm 80-200 g/m² |

| Max. inspection line speed | 300 m/min |

| Stable Inspection line speed | 250 m/min |

| Min. defect size (as a spot) | 0.1 mm²(contrast≥20) |

| Minimum defect size (as a line) | 0.1 mm × 5 mm(high contrast) |

| Min. color variance ( △ E) | △E≥3 |

| Multispectrsl color variances detected ( △ E) | △E≥1 |

| Min. registration deviation | ±0.1mm |

| Max. rewind diameter | 800mm |

| Core inner diameter | 120mm/150mm |

| Dimension(L×W×H) | 2500 × 1200 × 1600 (mm) |

| Gross weight | 1000 kg |

| Total power | 4.5 kW |

| Working power supply | AC380V 50Hz |

| Air pressure | 0.7—0.8Mpa 0.6m³/min |

Previous: Lope 1020

Next: DH-HJP 550/650/800/1100

CONSULTATION

15F Daheng Science & Technology Tower, No.3 Suzhou Str., Haidian District, Beijing China

+8610-82362836

E-mail: consult@daheng-imaging.com