Printing Inspection

Variable Data Inspection System

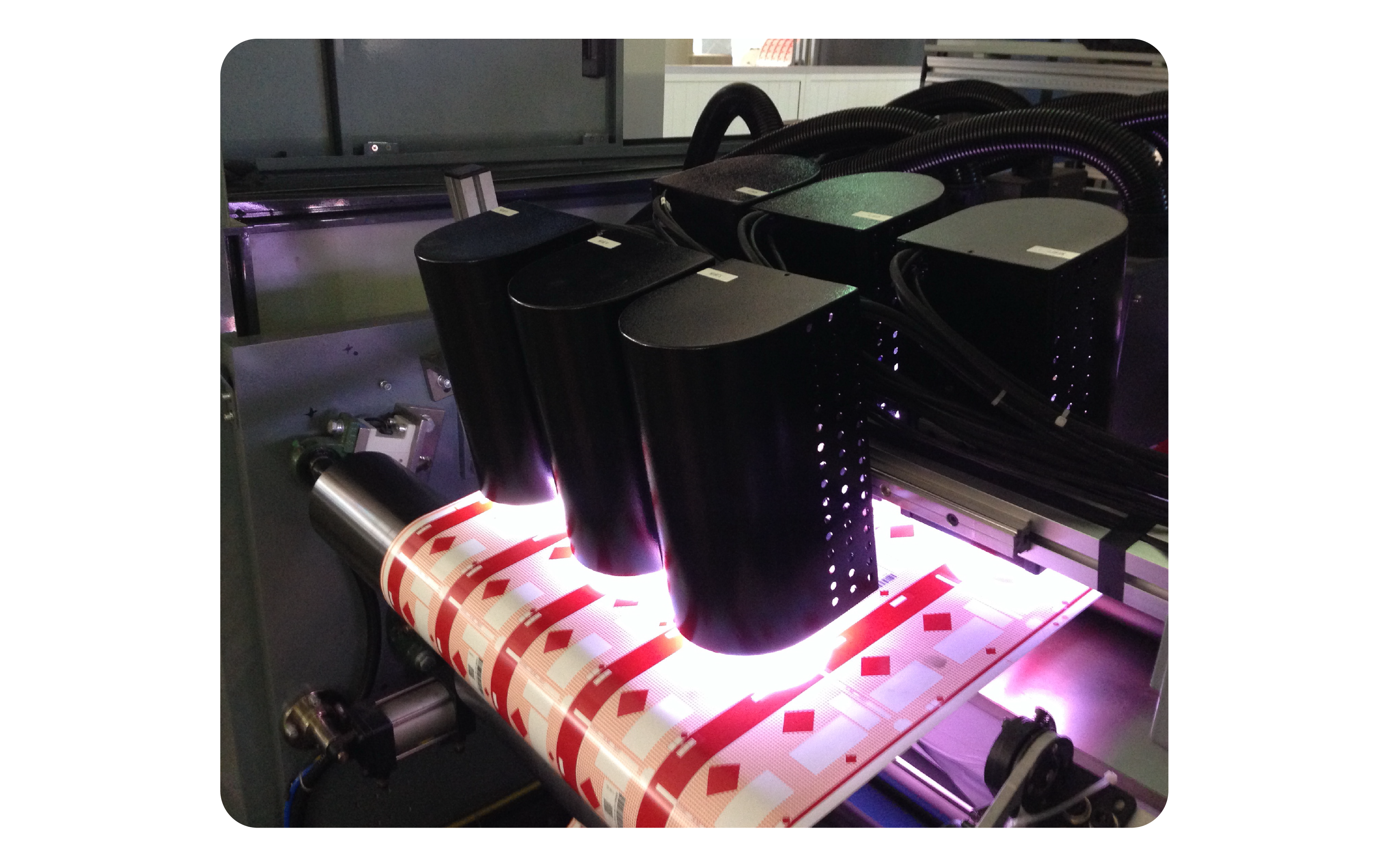

DH-VID100A can be installed on various printing machines and platforms to inspect variable information like barcodes and QR codes, both online and offline. It uses industrial cameras to scan, read, and compare the information with a database for quality control. If issues are detected, it triggers alarms and can reject defective items or halt the platform to prevent extensive waste.

- Product Features

-

Import production database files and compare them with recognized variable information

Real-time detection of variable data, promptly identifying issues like duplicates, errors, damage, or missing data, and triggering alarms for rejection

Simultaneously assess the printing quality of variable data, detecting issues like dirt, white spots, lines, ink problems, plate dirt, and misalignment

Real-time audio-visual alarms upon detecting quality problems, with options for real-time rejection, marking, stopping the machine, etc., based on machine capabilities

Automatically store inspection records in a database and generate inspection report files

User-friendly system operation, stable performance, and flexible installation

Products Overview

Specifications

| Item | Specification |

|---|---|

| Applied material | Ivory paper、Chrome paper、Gold/silver cardboard、Laser paper etc. |

| Max. inspected width | Customized |

| Image resolution | W:0.05mm ; L:0.05mm |

| Inspected speed | 300 m/min |

| Inspected defects | Variable data ● Number code; ● Barcode:Code128、ITF25、EAN13、Code39、EAN8、UPCA、 UPCE、UCC/EAN-128 ●Supervise code:Code128C+OCR ● QR code:QR、DM、PDF417 etc. |

| main inspected defects | ● Repead code,Wrong code,Bad code,No code etc. ●Spot,Missing print,color variance,wrinkle,registration etc. |

| Min. size of number | 2mm×1mm |

| Minimum defect size (as a point) | 0.10mm²(contrast≥20DN) |

| Minimum defect size (as a line) | W≥0.10mm,L≥5mm(contrast≥20DN) |

| registration | ±0.10mm |

| Defects handling | ● Audible and visual alarms ● Real-time display of defect images ● Recording defect information to a database, generating inspection record reports ● Automatic output of reject control signals |

Previous: DH-QZX820

CONSULTATION

15F Daheng Science & Technology Tower, No.3 Suzhou Str., Haidian District, Beijing China

+8610-82362836

E-mail: consult@daheng-imaging.com