Printing Inspection

DH-FH100

DH-FH100 is an inline inspection system working together with folding-gluing machines to read bar code on every pack to find out the confusion situation where other types of color packs are mixed up with the current type. As soon as a different type of pack is detected, the system will alert users with sound and light, stop the folding-gluing machine, and report the identification code and amount of the wrong type packs. The system can be mounted on any folding-gluing machine to guarantee that packs-confusion accidents will not happen.

- Product Features

-

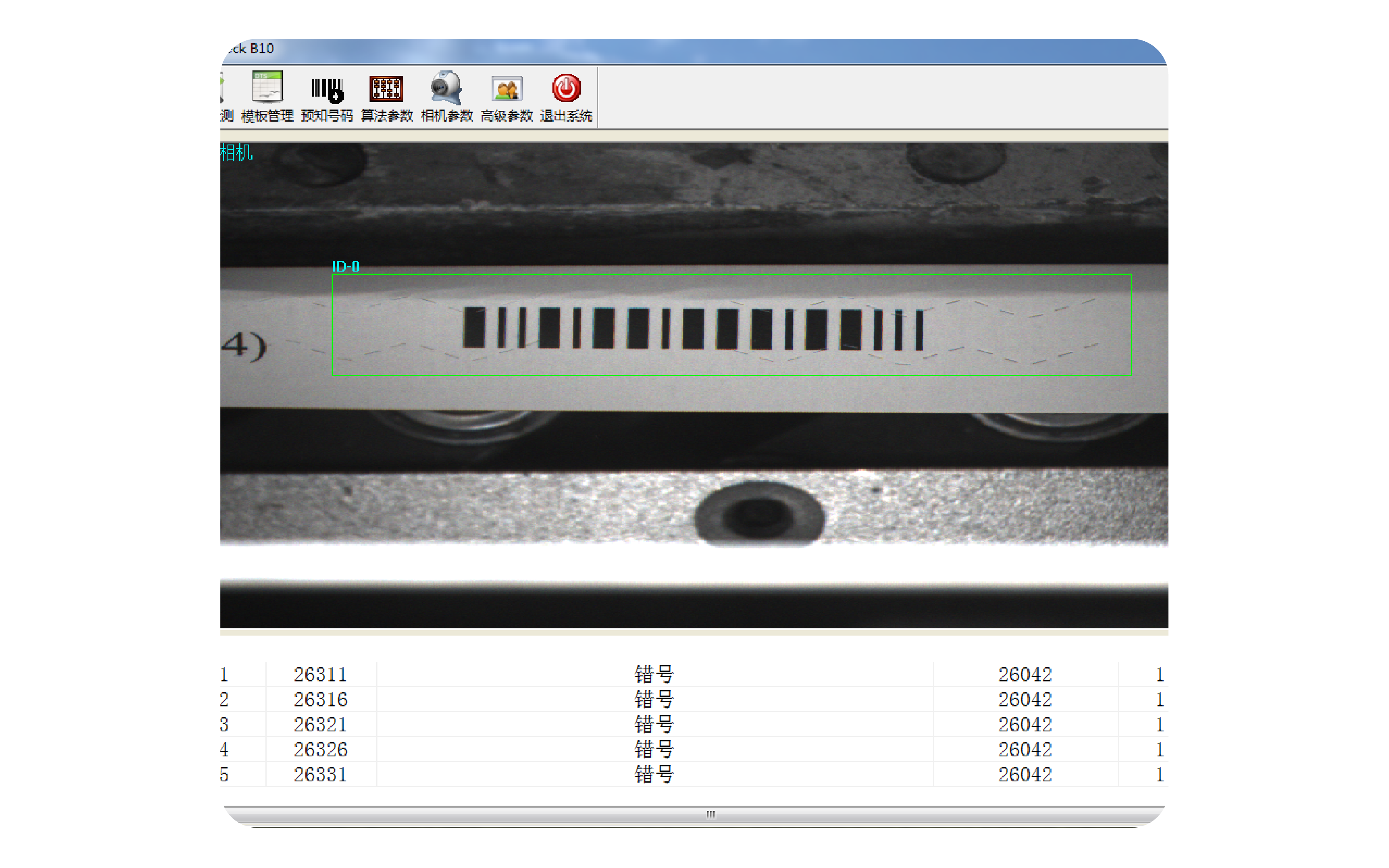

Real time monitoring barcodes, reading identification code on every pack’s body and comparing it with the specified ID

When pack confusion happens, system can provide sound and light alert, stop the folding-gluing machine, and display the type identification and the amount of the wrong packs

Real-time storing inspection results into database for further data analysis and quality management

Support for extensions to satisfy the inspecting task where a certain type pack having multiple bar codes

Products Overview

Software Interface

Specifications

| Item | Specification |

|---|---|

| Inspecting area size | 60mm×40mm |

| Barcode types | Code 128,Code 39,EAN 8, EAN13 etc. |

| Minimum barcode size (L×W) | 20mm×5mm |

| Maximum inspection speed | 260m/min |

| Installation space | 300mm×300mm×500mm |

| Defects-handling methods | Sound and light alert, stopping machine signal |

| Total power | 3kW |

| Working temperature | 5℃ - 35℃ |

| Relative humidity | 10-80%RH |

Machine Local Map

Previous: DH-MQ100

Next: DH-VID100A

CONSULTATION

15F Daheng Science & Technology Tower, No.3 Suzhou Str., Haidian District, Beijing China

+8610-82362836

E-mail: consult@daheng-imaging.com